BMR - MEDIUM RANGE - CATENA LTD. Official dealer Berco Spa.

Main menu:

BMR - MEDIUM RANGE

Our offerings

The Berco Medium Range offers an innovative,

reliable and economical set of solutions to your

undercarriage needs, catering for Original

Equipment Manufacturers (OEMs), the

Aftermarket, bulldozers, excavators, old machines

or special designs and providing you with the right

answer to your specific requirements.

THE WIDEST CHOICE

•A complete line of undercarriage componentsfor track-type machine classes ranging from 7 to50 ton and 140-215.9 mm (5.51"-81/2”) chainpitch• Dry, greased, sealed or lubricated chainversions, heavy duty chains and extreme-wearresistant bushings available upon request, morethan 11,000 configurations• More than 70 profiles of track shoes, morethan 4,000 configurations• Cast, forged or fabricated idler types, more than500 configurations• Single flange, double flange or inner flangerollers, more than 1,500 configurations• More than 600 configurations of sprockets andsegments• Arctic (-50°C) version and version for highspeedapplications• Undercarriage for special applications:conveyor, pipeline handling, milling mac

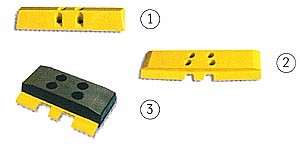

TRACK SHOES

• Over 70 different profiles with Single,

Double and Triple Grousers

• Cast steel shoes for special

applications: swamp type (1), flat type

(2), bent ends shoes, polyurethane

track shoes (3) and more

• Through hardened and stress relieved

to guarantee excellent wear, high

strength and resistance to bending and

breakage, resulting in longer life

TRACK SHOES

Undercarriage

for sugarcane harvester

for sugarcane harvester

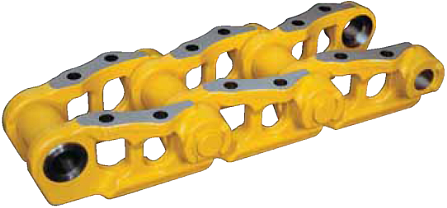

BERCO HEAVY DUTY TRACK CHAINS

FOR D4-D7 CLASS MACHINES

Heavy duty, sealed & lubricated track chains have been

specifically designed for increased pin & bushing

retention. Track link incorporates greater pin-to-link

and bushing-to-link contact areas while additional

link wear material increases component life. D5 and

D6 heavy duty chains are also available in the version

with Extreme Wear Resistance Bushings for

maximum life in high abrasion environment.

GREASED TRACK CHAINS

FOR EXCAVATORS AND HEAVY DUTY

APPLICATIONS

A completely new sealing system, consisting of a

W shape polyurethane seal, especially designed to

keep grease in joints and abrasive particles out of them

• Internal pin & bushing wear reduction, with consequent

life extension for 20% and more if compared with the

standard sealed chains on the same application

• Reduction of sneaky tracks phenomenon, as result

of more laterally stable chains, thus reducing wear of

related parts, such as links, rollers, guides

• Improved rebuildability of the track chain

• Noise and maintenance costs reduction and less

machine fuel consumption: improved travelling

performances

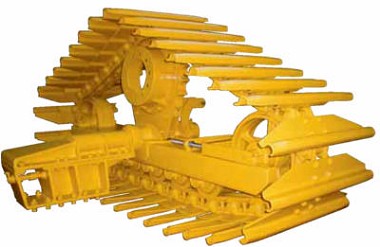

TRACK CHAINS

Undercarriage for rice

combine harvester

combine harvester

FORGED IDLERS

• Hot forged idlers for 15-40 ton class excavators andfor D6R class dozers• Hot forging gives optimuminternal grain flow andstronger coreresistance• Induction hardenedrail surface forexcellent resistanceto wear and fatigue• Heavier components forimproved stability• No “drum effect”noise resonance

FORGED SPROCKETS

• Hot forged sprockets for 10-40 ton class excavatorsand for D3-D4 class dozers• Nine chain pitch versions from 159.8 to 228.6 mm(6.29”-9”)• Hot forging gives optimum internal grain flow andstronger core resistance• Single shot induction hardened on entire toothprofile or with differential quenching for excellentresistance to wear and fatigue

FORGED IDLERS

| CLASS D3-D4 B/C Pitch: 155,5 ММ |  | CLASS D5M Pitch: 171,5 ММ |

| CLASS D6M Pitch: 190 ММ |  | CLASS D6R Pitch: 203,2 ММ |

| CLASS D7N/R Pitch: 215,9 ММ |  | CLASS D8N/R Pitch: 215,9 ММ |